- Product details

- Product labeling

1: Product line

Model: dw-sw series

Type: water cooled cooling (external cooling water source is required, generally referring to cooling water of water tower)

Refrigeration capacity range: 100kW~2500kw

Temperature control accuracy: ± 1 ℃~± 2 ℃ (high precision ± 0.5 ℃ can be customized)

Temperature range: 5 ℃~35 ℃ (customized low-temperature effluent 2 ℃)

Customizable: Yes

Delivery date: 15~30 working days

Note: space is limited for more product details, please contact our sales staff. We will provide solutions for different processes and equipment!

2: Product overview:

The water-cooled screw chiller is named water-cooled screw chiller because its key component compressor is screw chiller. The state of the unit from the evaporator is the refrigerant of gas; After adiabatic compression by the compressor, it becomes a high temperature and high pressure state. The compressed gas refrigerant is cooled and condensed at constant pressure in the condenser. After condensation, it changes into liquid refrigerant, and then expands to low pressure through the throttle valve to become a gas-liquid mixture. The liquid refrigerant at low temperature and low pressure absorbs the heat of the cooled material in the evaporator and becomes a gaseous refrigerant again. The gaseous refrigerant enters the compressor again through the pipeline to start a new cycle. These are the four processes of freezing cycle. It is also the main working principle of screw chiller.

Advantages of screw compressor:

1. high reliability. Screw compressor has few spare parts and no wearing parts, so it has reliable operation and long service life,

2. convenient operation and maintenance.

3. good power balance. Small size, light weight, less floor space.

4. the energy efficiency ratio of refrigeration capacity is higher than that of scroll machine

3: Application fields

Davosi water cooled screw chiller. It is widely used in chemical reaction, extrusion, aluminum alloy processing, food processing, medicine, concrete mixing, centralized freezing station, refrigeration and other fields requiring refrigeration and cooling. Davosi has been committed to refrigeration for many years and has a number of industry technical elites. Constantly improve and optimize the products. Our company provides customers with all-round technical support for model selection, installation and commissioning.

4: Unit characteristics:

1. Many high-efficiency and energy-saving compressors, such as Bitzer (Germany), Hanbell (Taiwan), Fusheng (Taiwan) and other imported international brands, are used to match high-quality condensers and evaporators, with high efficiency, stable performance, low noise and long service life. The industrial PLC unit is centrally controlled and equipped with the energy ratio of the compressor, which can timely and accurately control the matching of the refrigerating capacity and cooling load of the unit, ensure the effective operation of the unit and reduce the operation cost

2. Internal integration of multiple safety protection and processing functions such as water cut-off, low temperature, high and low voltage, antifreeze, phase loss, delayed start, inverse phase overload motor, overheating and oil pressure difference

3. All Chinese operation interface, menu prompt, can set the unit operation status and home appliance operation environment at will

4. The capacity control can adopt four section type (****-75%-50%-25%) or three section type (****-66%-33%) and non section type control system

5. The unique built-in oil pressure system ensures that the compressor maintains lubrication effect without oil pump. The oil separator adopts double-layer filtering method, which has good oil filtering effect, and the heat converter can play a large role

6 high efficiency internal thread copper pipe, enhance heat transfer effect, more energy-saving and efficient. Using cad/cam design and processing technology, the CNC machining center has been completed, with compact structure, small size of 15, and durability for months. The U-shaped heat exchange tube bundle is convenient for maintenance and prevents refrigerant leakage

5: (1) machine picture:

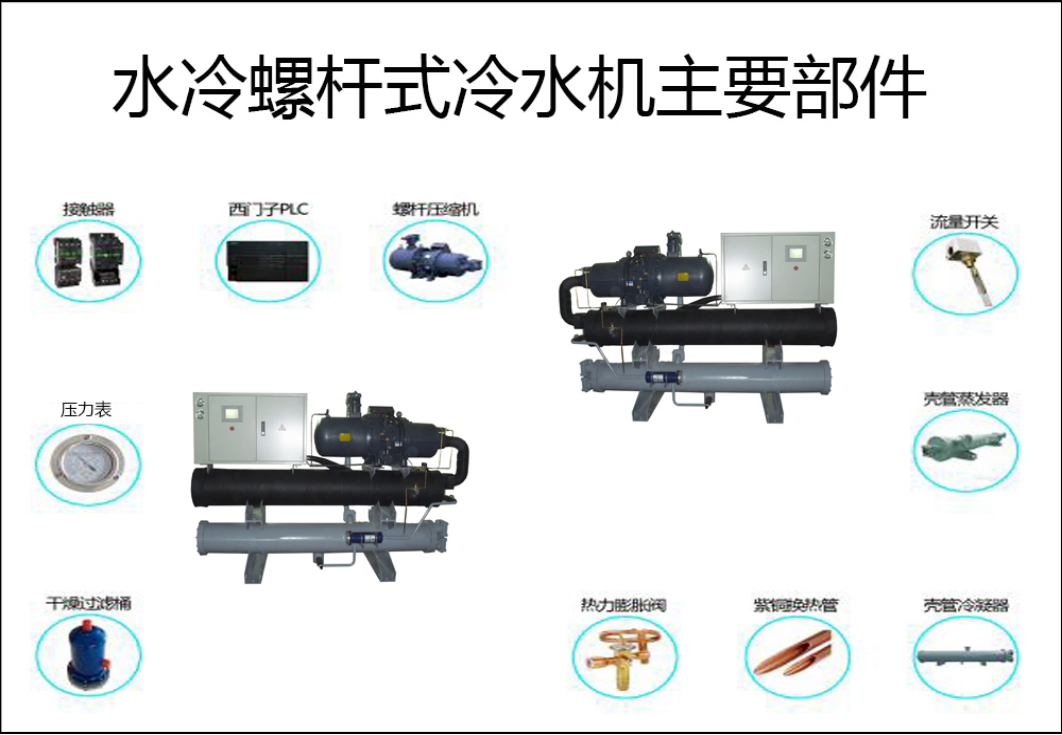

(2) : water cooled screw chiller composition:

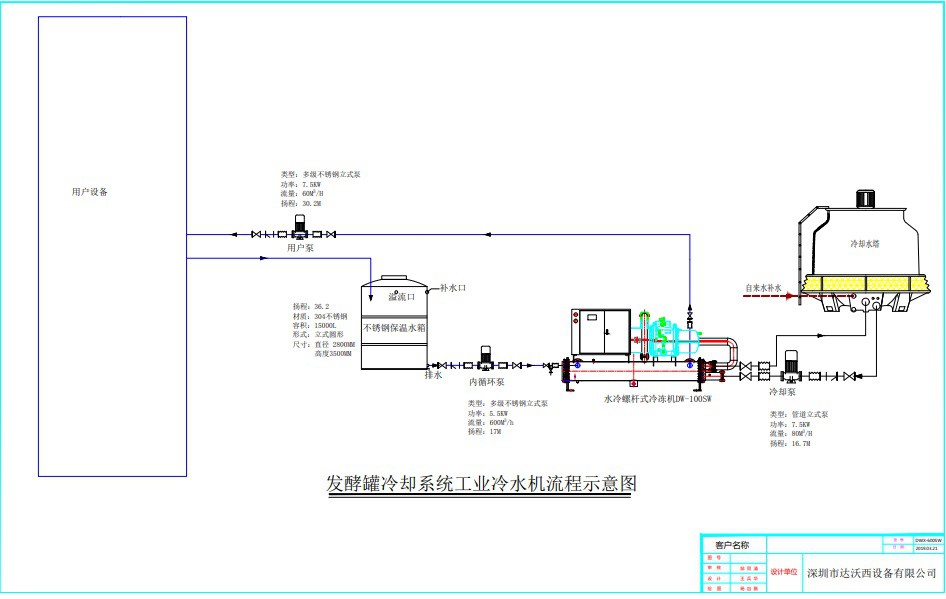

(3) Schematic diagram of customer process flow

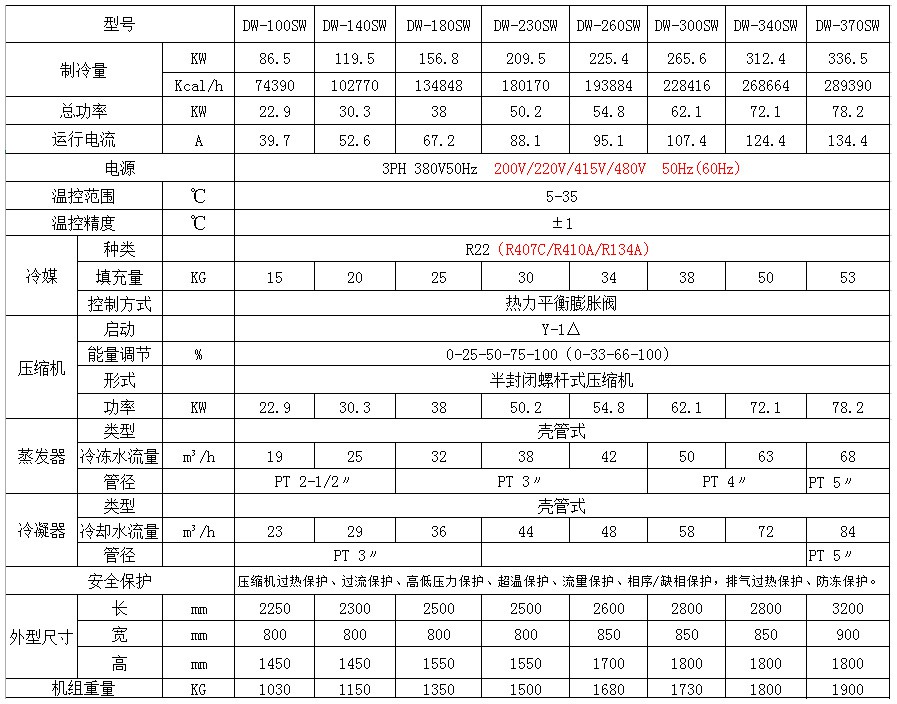

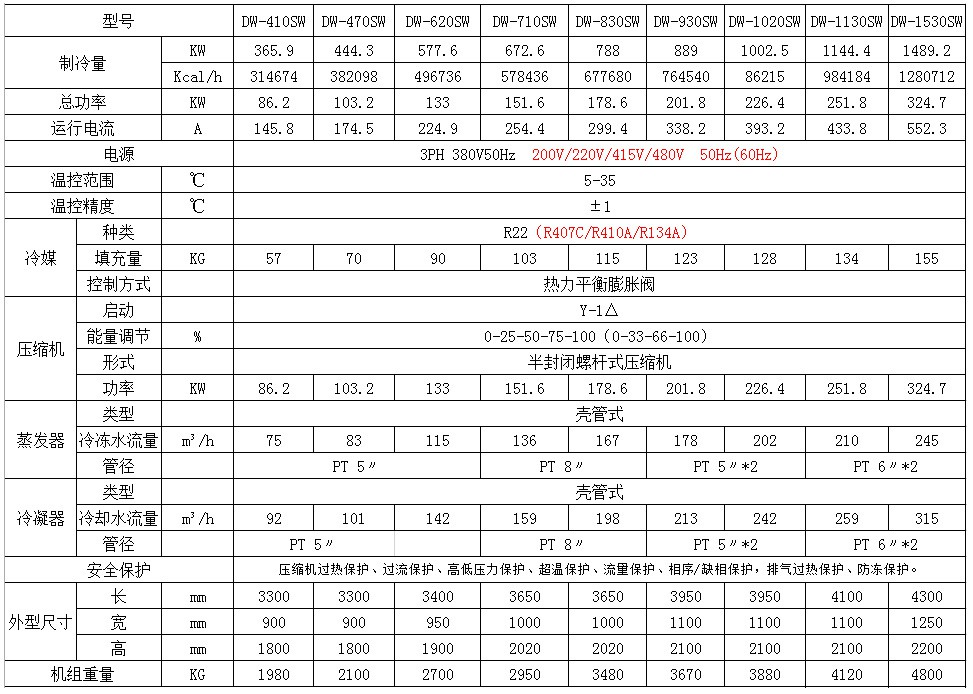

6: Water cooled screw chiller (single compressor)

Water cooled screw chiller (single compressor)

Remarks: 1. the refrigerating capacity is based on: chilled water inlet and outlet temperature of 12 ℃/7 ℃, cooling water inlet and outlet temperature of 30 ℃/35 ℃ (nominal refrigerating capacity)

2. working range: chilled water temperature range: 5 ℃~ 35 ℃; Chilled water inlet and outlet temperature difference: 3 ℃ to 8 ℃ control accuracy ± 1 ℃~± 2 ℃

3. use in the environment with the ambient temperature not higher than 40 ℃ and ensure good ventilation

4. the above parameters are standard model parameters. If you have any, please call! Reserve the right to change the above parameters or dimensions without notice