- Product details

- Product labeling

1: Product line

Model: dw-sa series

Type: air cooled cooling (external rotor fan)

Refrigeration capacity range: 100kW~1000kW

Temperature control accuracy: ± 1 ℃

Temperature range: 5 ℃~ 35 ℃

Pump pressure: 2kg~8kg (customized according to requirements)

Customizable: Yes

Delivery date: 15~30 working days

2: Product overview:

The air-cooled screw chiller is named as the air-cooled screw chiller because its key component compressor is screw type. The state of the unit from the evaporator is the refrigerant of gas; After adiabatic compression by the compressor, it becomes a high temperature and high pressure state. The compressed gas refrigerant is cooled and condensed at constant pressure in the condenser. After condensation, it changes into liquid refrigerant, and then expands to low pressure through the throttle valve to become a gas-liquid mixture. The liquid refrigerant at low temperature and low pressure absorbs the heat of the cooled material in the evaporator and becomes a gaseous refrigerant again. The gaseous refrigerant enters the compressor again through the pipeline to start a new cycle. These are the four processes of freezing cycle. It is also the main working principle of screw chiller.

3: Application scope:

Davao west air cooled screw chiller. It is widely used in chemical industry, extrusion, aluminum alloy processing, food processing, medicine, refrigeration and other fields requiring refrigeration and cooling. Davosi has been committed to refrigeration for many years and has a number of industry technical elites. Constantly improve and optimize the products. Our company provides customers with all-round technical support for model selection, installation and commissioning.

4: Product features:

1. The compressor is an international brand. The imported international brand, Bitzer, Germany (bizel), lefkang, Italy, Hanbell, Taiwan, China (Hanzhong), is used as the compressor. The efficiency of the new high-efficiency screw rotor compressor is 20%-30% higher than that of the general compressor, and has obtained the IS9001 international quality certification of European and American patents.

2. High efficiency 5:6 patented asymmetric rotor tooth profile.

3. The capacity control can adopt four section (****-75%-50%-25%) or three section (****-66%-33%) and non section control systems.

4. The combined design of 11 bearings and A-type axial thrust balance drum greatly improves the bearing life by 2.5-3.5 times.

5. It adopts high-efficiency silicon steel sheet special groove design, and is equipped with internal and external omni-directional cooling channels, so that the compressor motor can play a high efficiency under any load.

6. The unique built-in oil pressure system ensures that the compressor can maintain the lubrication effect without oil pump. The oil separator adopts double-layer filtering method, with good oil filtering effect, and the heat exchanger can play a large role.

7. High efficiency, low noise, low vibration.

8. A variety of refrigerants can be selected. In addition to R22 refrigerant, R134a, R407C and other environmentally friendly refrigerants can also be selected.

9. Full range of compressor volume ratio (vi=2.2/2.6/3.0/3.5) for selection It can effectively avoid additional energy consumption caused by over compression or under compression.

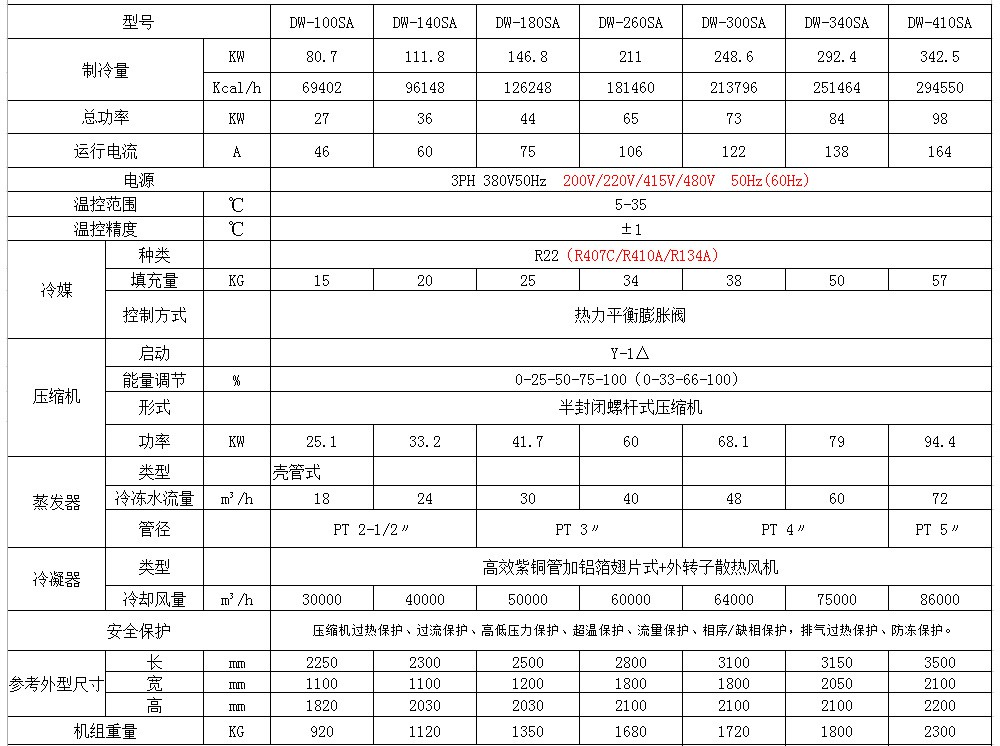

5、 Technical parameters of air-cooled screw chiller (single compressor):

Remarks: 1. refrigeration capacity is based on: chilled water inlet and outlet temperature 12 ℃/7 ℃, condensation temperature 40 ℃ (nominal refrigeration capacity)

2. working range: chilled water temperature range: 5 ℃~ 35 ℃; Chilled water inlet and outlet temperature difference: 3 ℃ to 8 ℃ control accuracy ± 1 ℃~± 2 ℃

3. use in the environment with the ambient temperature not higher than 35 ℃ and ensure good ventilation

4. the above parameters are standard model parameters. If you have any, please call! Reserve the right to change the above parameters or dimensions without notice

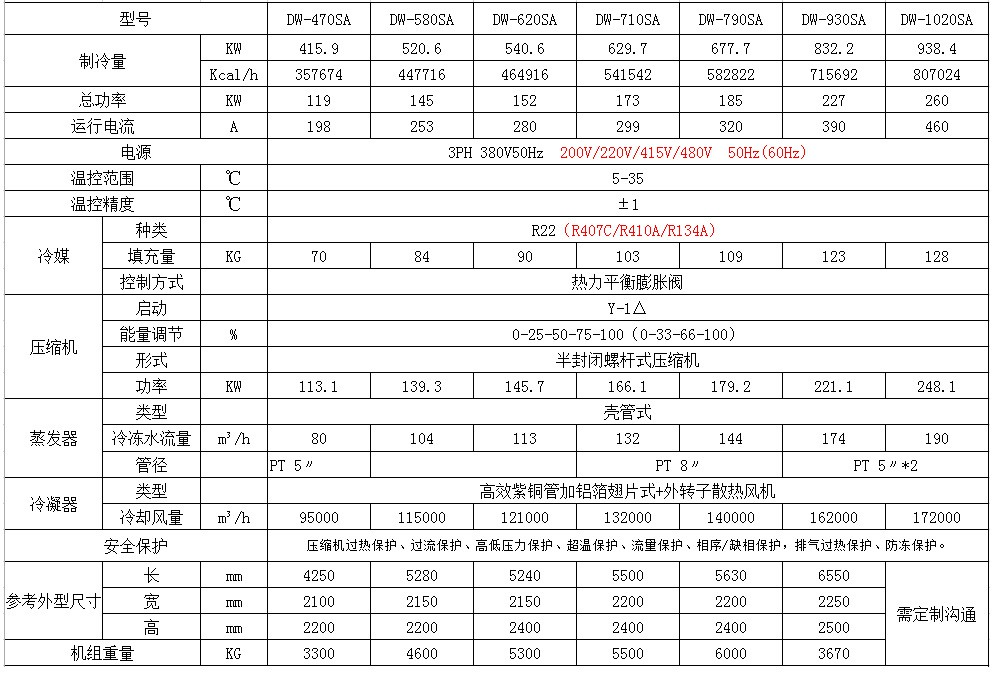

Technical parameters of air-cooled screw chiller (single compressor):

Remarks: 1. refrigeration capacity is based on: chilled water inlet and outlet temperature 12 ℃/7 ℃, condensation temperature 40 ℃ (nominal refrigeration capacity)

2. working range: chilled water temperature range: 5 ℃~ 35 ℃; Chilled water inlet and outlet temperature difference: 3 ℃ to 8 ℃ control accuracy ± 1 ℃~± 2 ℃

3. use in the environment with the ambient temperature not higher than 35 ℃ and ensure good ventilation

4. the above parameters are standard model parameters. If you have any, please call! Reserve the right to change the above parameters or dimensions without notice